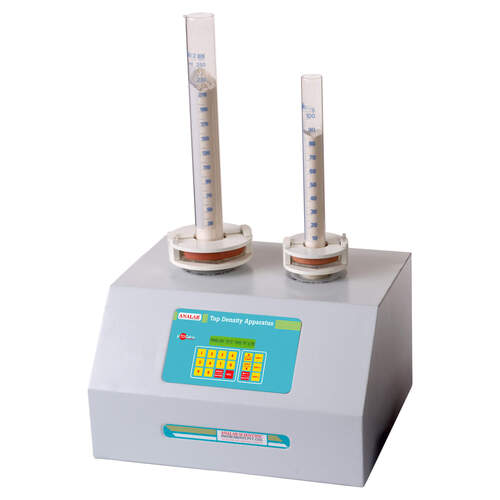

Tap Density Test Apparatus - Model : TDCal10

58600 INR/Number

Product Details:

- Power Source Main supply AC power

- Accuracy High precision tapping; measurement accuracy as per USP/BP/IP standards

- Voltage 230V AC, 50Hz

- Measurement Range Powder volume: up to 250 ml (depending on cylinder)

- Temperature Range Ambient

- Feature Pre-settable timer, automatic stop, variable cylinder set, adjustable speed

- Core Components Motor, control panel, cylinders

- Click to View more

X

Tap Density Test Apparatus - Model : TDCal10 Price And Quantity

- 58600 INR/Number

- 1 Number

- 3 ± 0.2 mm standard

- Low maintenance design

- Manual and automatic modes

- Overload protection and safety lock

- Anti-corrosive powder coating

- Powder and granules

- Calibrated with certified mass for calibration check

- 0-9999 seconds pre-settable digital timer

- Two graduated glass cylinders (custom type available upon request)

- Up to 250 ml

- Up to 80% RH

Tap Density Test Apparatus - Model : TDCal10 Product Specifications

- 400 x 300 x 400 mm

- Main supply AC power

- High precision tapping; measurement accuracy as per USP/BP/IP standards

- 14 kg approx.

- Ambient

- Tap Density Test Apparatus

- Measurement of tap density of powder material

- Powder volume: up to 250 ml (depending on cylinder)

- 230V AC, 50Hz

- Powder coated mild steel body; glass cylinders

- Pre-settable timer, automatic stop, variable cylinder set, adjustable speed

- Motor, control panel, cylinders

- Single and double cylinder operation (up to 250 ml) - Interchangeable cylinders for variable sample volume

- Digital LCD display

- TDCal10

- Semi Automatic

- Adjustable tapping frequency - selectable (typically 300 or 250 taps/min)

- 3 ± 0.2 mm standard

- Low maintenance design

- Manual and automatic modes

- Overload protection and safety lock

- Anti-corrosive powder coating

- Powder and granules

- Calibrated with certified mass for calibration check

- 0-9999 seconds pre-settable digital timer

- Two graduated glass cylinders (custom type available upon request)

- Up to 250 ml

- Up to 80% RH

Product Description

Tap Density Test Apparatus - Model: TDCal10 is perfect for determining the tapped density of powders, granules, pellets, flakes, and other materials. Friction-free bearings guarantee that the cylinder drops freely from the desired height. The tapped density, compressibility index, and Hausner ratio are computed and shown at the end of the test. Tap Density Test Apparatus - Model: TDCal10 provides a measure of powder cohesiveness, which is related to flowability. Because of its simplicity and speed of measurement, tapped density is a preferred metric for powder characterization.

Highly Accurate Density Measurement

TDCal10 provides reliable measurement of tap density for powder materials, with high precision tapping and certified calibration checks ensuring compliance with major pharmacopoeia standards. Adjustable tapping frequency and interchangeable cylinders allow adaptability to diverse samples and testing conditions.

Versatile Sample Processing

The apparatus supports both single and double cylinder operation, with sample capacities up to 250 ml. It is suitable for powders and granules, making it ideal for applications in pharmaceutical, chemical, and material testing laboratories. Custom cylinder options further enhance its versatility.

Exceptionally Safe and Durable

The instrument features overload protection, a safety lock, and an anti-corrosive powder-coated finish, ensuring user safety and extended equipment life. Its robust construction, combined with low-maintenance design, makes it a suitable choice for rigorous laboratory use.

FAQ's of Tap Density Test Apparatus - Model : TDCal10:

Q: How does the TDCal10 Tap Density Test Apparatus operate?

A: TDCal10 can be operated in both manual and automatic modes. The user places the sample in the graduated cylinders, sets the desired tapping frequency and timer digitally, and initiates the test. The apparatus then performs controlled tapping, automatically stopping after the set time or number of taps.Q: What types of samples are compatible with TDCal10?

A: TDCal10 is specifically designed for powder and granule samples. It includes interchangeable glass cylinders to accommodate variable sample volumes, supporting up to 250 ml per cylinder. Custom cylinder designs are available on request for specialized applications.Q: When should calibration and maintenance be performed?

A: Routine calibration can be conducted using certified mass standards, as recommended by regulatory guidelines. TDCal10 requires minimal maintenance due to its low-maintenance design; periodic cleaning and inspection are suggested to ensure optimal performance and measurement accuracy.Q: Where is TDCal10 typically used?

A: TDCal10 is widely employed in laboratories within pharmaceutical, chemical, and material testing industries for determining tap density of substances. It is suitable for settings that require compliance with USP, BP, or IP measurement standards and accurate density data.Q: What is the process for measuring tap density using this model?

A: The sample is placed in the graduated cylinder and initial volume is recorded. The apparatus then taps the material at a user-selected frequency and time. After completion, the final compacted volume is measured, and the tap density is calculated by dividing sample mass by its tapped volume.Q: How does TDCal10 ensure measurement accuracy and user safety?

A: TDCal10 meets USP/BP/IP standards for tap density measurements. It features overload protection, a safety lock, and an anti-corrosive finish to prevent damage and maintain user safety throughout operation. Calibration checks further confirm ongoing measurement reliability.Q: What benefits does using TDCal10 offer?

A: Using TDCal10 delivers accurate, repeatable tap density results, high operational safety, and flexible handling of various sample sizes. Its low-maintenance design, robust construction, and compliance with international standards make it an efficient and reliable choice for laboratory professionals.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS